Retention of Blades Test

A flush or self-contained receptacle having a 5-15R,5-20R,6-15R, or 6-20R configuration shall be subjected to the retention of blades test described in this Section.

Exception: A receptacle having a 1-15R,5-15R,5-20R,6-15R, or 6-20R configuration and not of the flush or self-contained type may instead be subjected to the Retention of Plugs Test, Section 116.

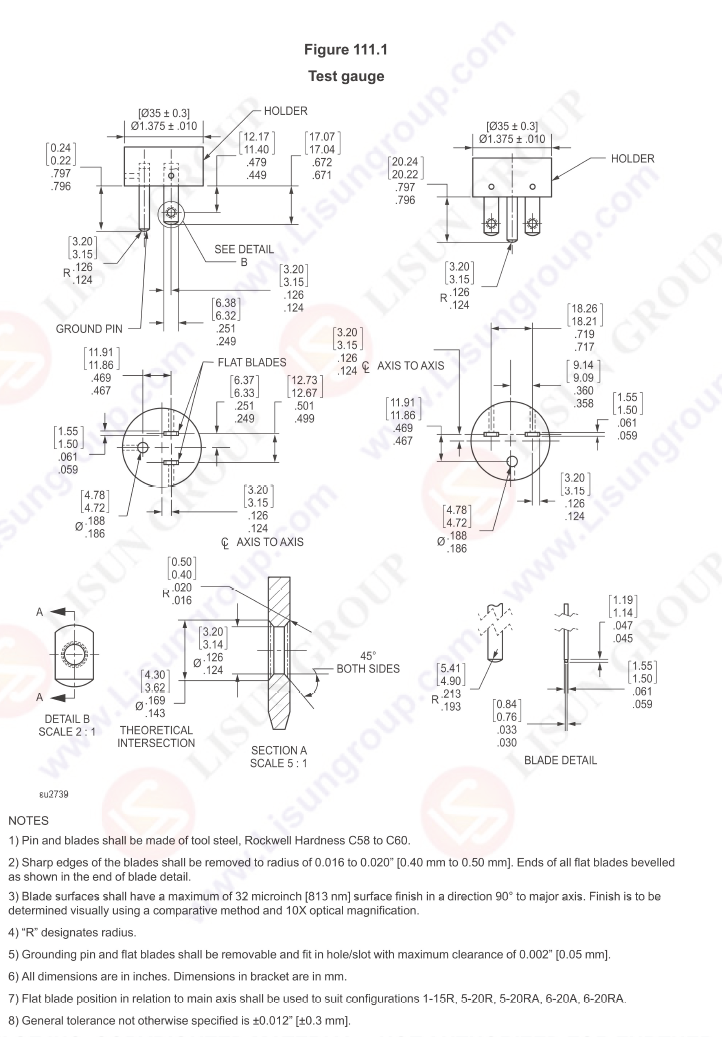

Receptacles having the break-off tab, when provided, removed from one nonidentified terminal are to be subjected to ten conditioning cycles of manual insertion and withdrawal of a standard test gauge, see Figure 111.1. Each of six devices is to be tested. The gauge is to be configured as outlined in Table 111.1. The force applied to insert the gauge for any of the conditioning cycles is not to exceed 40 lbf (178 N). The gauge is to have the dimensions indicated in Figure 111.1 but is not to have holes in the outer ends of the blades.

Test Gauge with UL498 Figure 111.1

The standard test gauge is to be configured as shown in Table 111.2 using the line blades without holes and with the grounding blade removed. The gauge is then to be inserted in the receptacle and a static 3 lbf (13.3 N) (including the weight of the gauge), which tends to remove the gauge from the receptacle, is to be applied for a period of 1 minute in a direction normal to the plane of the face of the receptacle. There shall not be more than 0.079 inch (2 mm) displacement of the gauge.

The standard gauge is to be configured as shown in Table 111.3 using the line blades with holes in the end and with the grounding blade in place. The test is to be conducted using the apparatus as described in Figure111.1A. The test gauge is attached to the apparatus as shown. The apparatus consists of a principal mass, and a supplementary mass. The supplementary mass is 1.5 lbs (6.7 N). The principal mass, together with the supplementary mass, the Gage and any hardware equals 15 lbs (67 N) total. The gage is inserted fully into the device.

The principal mass and associated hardware is hung on the gage without jolting. The gage shall not remain in the receptacle. If the gage does not withdraw the supplementary mass is raised and allowed to fall from a height of 2 in (51 mm) onto the principal mass one time. The gage shall not remain in the receptacle. A test apparatus that does not incorporate a supplementary mass and equals the 15 lbs (67 N) total is permitted if agreeable to all parties.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

https://www.lisungroup.com/news/technology-news/test-gauge-with-ul498-figure-111-1.html

.jpg)

Comments

Post a Comment